Imagine you’re setting up your industry and you have connected all your electrical equipment with a servo voltage stabilizer. Then one day, there is a huge voltage spike in the mains power supply that goes on for only 1 second.

But within that 1 second, all your industrial machinery is already damaged. Despite having a servo connected, it couldn’t really protect your equipment against voltage fluctuations.

We recently had a client who bought a machine for 1 Cr. During the event of a voltage surge, his machine sparked and stopped working. On analyzing the problem, we found that the PCB of his machine was damaged due to voltage fluctuations. And this was despite having a servo voltage stabilizer connected. The cost of getting this PCB changed was 20 lakhs itself, almost one-fifth the price of the machine.

Does this sound scary? Have you faced this challenge already before? Then you are in the right place.

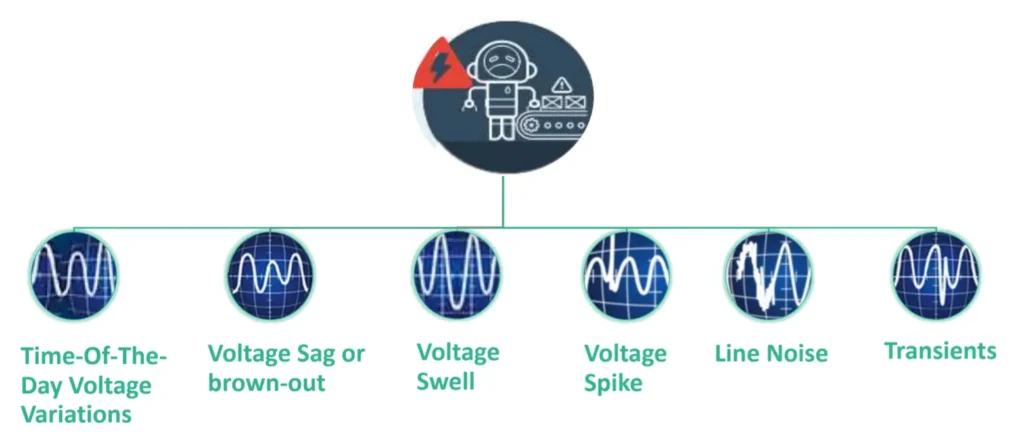

To know in detail about voltage fluctuations, read our article: Voltage fluctuations

The Change in the Face of Electricals

If we look back a few years, electrical machines were solely electrical – with large, rugged components that could withstand the impact of heat, current and voltage changes.

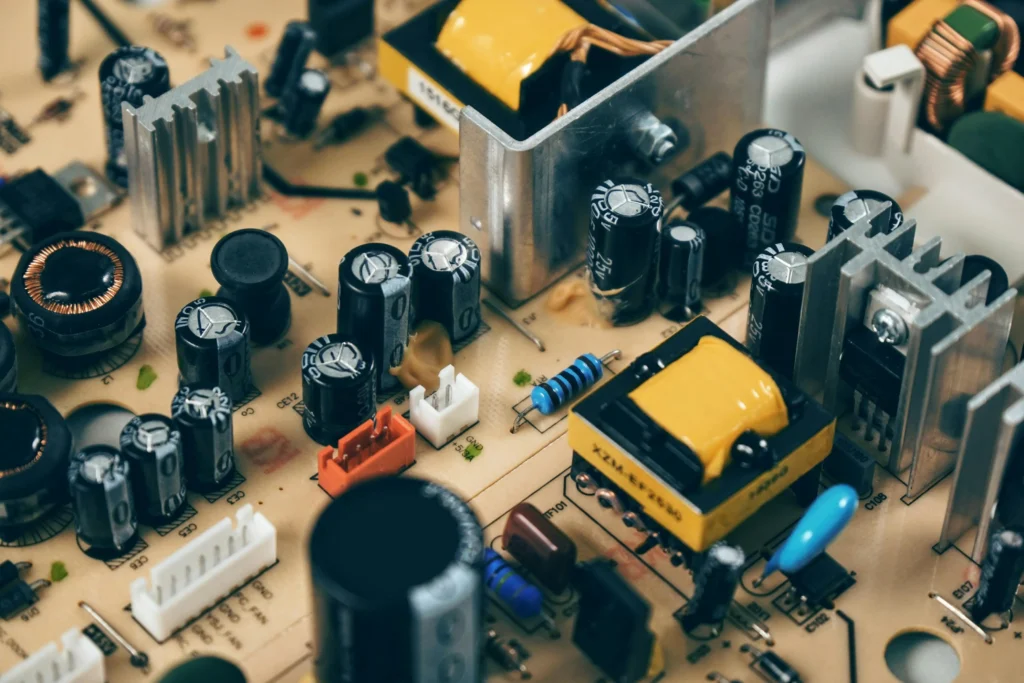

But over the past few years, electricals have changed. Almost every modern day electrical is equipped with a small electronic card, or PCB. These electronic cards have made the machines more efficient, reduced industrial downtime and improved performance significantly. But these electronic cards come with small sensitive components like transistors, resistors, capacitors, with sensitive soldered connections as well.

Traditional technologies like servo voltage stabilizer were invented to help manage voltage fluctuations in electrical equipment, but since long we have been employing this obsolete technology for modern day machines too. Unfortunately, servo stabilizers fail to address the issue with voltage fluctuations when taking into account electronic chips and other sensitive components.

The Problem with Servo Voltage Stabilizer

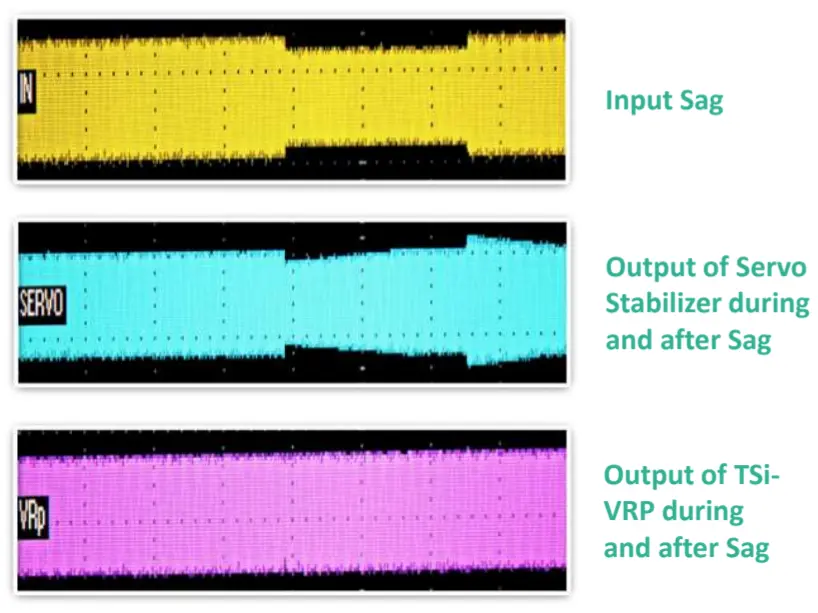

A servo stabilizer can take up to 30-40 seconds to correct the voltage. This is because it makes use of electromechanical motors that help stabilize the voltage through the power supply.

Now this may have worked in the past, when voltage correction was meant to be only for electrical equipment, but it fails for electronic equipped electricals.

Shortcomings of the Servo Voltage Stabilizer

- It doesn’t address instantaneous spikes, sags and transients.

- It fails to take into account regenerative load.

- It consists of moving parts which increase maintenance costs.

- It requires oil cooling.

- When voltage returns to normal in the mains supply, it takes time to normalize the corrected voltage, thereby generating voltage fluctuations of its own.

- It is not solar compatible.

- Its working efficiency is only 80%, therefore uses significant electricity on its own.

Essentially, servo is not only problematic, but also damaging for your electrical equipment.

VRP to the Rescue

Think about it – if you could have a voltage stabilizer that conditions voltage in 20 milliseconds (1/50th of a second), how cool would it be? And what if it has no moving parts that reduces the maintenance cost to zero? In this case, it won’t even require cooling because no heat is being generated. And lastly, what if it is bidirectional, making it compatible for regenerative load and solar connection?

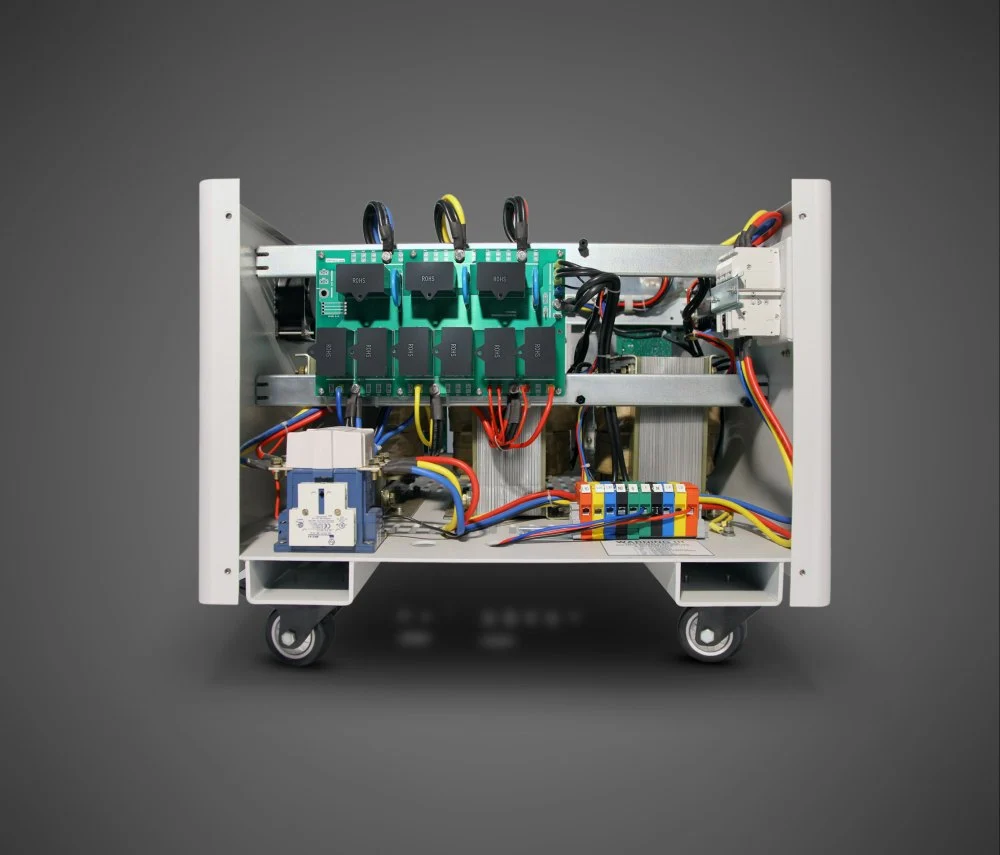

VRP is exactly that. VRP is a static IGBT voltage conditioner that works on the principle of Pulse Width Modulation (PWM). This allows it to correct voltage in one waveform of AC current. In India, one waveform equals 20 milliseconds, so the voltage is corrected within that time.

This rapid speed of voltage correction efficiently protects your electrical equipment against voltage fluctuations, swells, spikes, sags, line noise and transients. It is the best available voltage stabilizer for automotive, textile, robotics, or any other industry – you name it.

VRP is a product by TSi Power, a US-based power systems company. In India, it is manufactured in Vadodara, Gujarat, at Tsi Power’s own manufacturing facility.

Today, VRP has been adopted by multiple renowned companies like HAAS CNC, Amazon, Tata Motors, Hyundai, Fanuc, Hindustan Petroleum, Sun Pharma, World Health Organization, and many more names – the list falls short.

Why VRP?

- A voltage stabilizer that provides instant, real time, precise, step-less voltage correction with excellent load compatibility.

- Corrects voltage in merely 20 milliseconds, which is 1/50th of a second, enough to protect against sensitive electrical equipment.

- Provides Overvoltage, Undervoltage, Phase Reversal and Phase Loss protection.

- Consists of no moving parts, reducing maintenance costs to zero.

- Working efficiency is 98%, therefore uses almost negligible electricity of its own, helping you reduce electricity costs.

- Offers exceptional handling of regenerative loads.

- The sole voltage stabilizer that offers bidirectional functionality, making it solar compatible.

- Provides the best protection for CNC and electronic machines.

- Offers plug and play functionality, making the installation and service hassle-free.

- Doesn’t require any external air conditioning or cooling system.

Choosing the Right Technology

Change and innovation is the way of the world. Growth requires adaptability, and moving on to newer and better technologies is important to ensure we are aligned with the fast pace of the advancing world. Whatever your requirement may be, the VRP is the ideal choice.

Servo voltage stabilizer is an excellent technology, but it has turned obsolete. Industries and industrial machines have undergone massive technological advancements over the years, but still our choice in a stabilizer has not changed.

We need to understand that modern problems require modern solutions. And VRP is a modern solution to all your voltage related modern problems.

Benefits Offered by the VRP

- Protects your expensive machines.

- Helps streamline workflow so that your industry never stops.

- Saves you a ton of money you spend on maintenance and repair every year.

- Provides protection against over and under voltage, phase loss and phase reversal.

Models

1. VRP: The basic voltage stabilizer that provides real time precise voltage correction.

2. NPS VRP: A VRP with its own inbuilt neutral. This model deals with the common issue of Neutral loss or weak Neutral by generating its own neutral. Beneficial for industries that regularly face issues with Neutral connection.

3. HAPS VRP: A voltage stabilizer suited specifically for single phase connection. The HAPS VRP automatically selects two healthy phases, combines them into one using a step-down transformer and provides a seamless connection for single phase loads. This helps keep your load running despite the loss of one phase.

FAQs

Q1: What is a voltage surge and sag?

Answer: A voltage surge is an event of sudden rise in voltage that occurs for milliseconds or microseconds. A sag in an event of drop in voltage, which causes a sudden rise in electric current. Both the sag and surge can be detrimental for a machine. Using a voltage stabilizer that can control these sudden changes is extremely important.

Q2: Why are electronics more sensitive to voltage fluctuations?

Answer: Electronics consist of small parts, including some that are semiconductor based. Considering the physics of semiconductors, they act as a conductor only under certain voltage conditions. This makes them sensitive to rapid changes in voltage. Electronic components can withstand a voltage that confirms to ITIC Curve 2000. Therefore, it is necessary to choose a voltage stabilizer that corrects voltage in line with the ITIC Curve.

Q3: Is the VRP compatible for all three phase and single-phase loads?

Answer: Yes, the VRP is compatible with all types of loads. In fact, it is available in HAPS model, which is specifically designed for single phase load. Users also have the option to get an IPC (Independent Phase Controller) with the VRP to ensure power availability in other phases in case of loss of one phase.

Q4: Is it necessary to get a voltage stabilizer?

Answer: Getting a voltage correction system is now more important than ever. With increasing climate unpredictability, especially in summers in India, power distribution is significantly impacted. Poor infrastructure and supply and demand variations have resulted in major voltage fluctuation problems, causing destructive damage to electrical equipment.

Conclusion

Industrial machinery today is highly sophisticated and sensitive to sudden changes in voltage. Even though servo voltage stabilizer is proficient in handling voltage fluctuations, it takes a lot of time to do that. Within that timeframe, your machines have already faced enough damage to cost you a lot of money. Investing in a technology that corrects voltage within milliseconds is extremely essential to ensure a smooth workflow and save money.

The VRP overcomes all the shortcomings of a servo voltage stabilizer and provides additional benefits of its own. This makes it an outstanding innovation in the field of voltage conditioning that is the need of the hour for industries in today’s time. Moreover, with the increased investment in renewable energy like solar, static power conditioner stands out as the sole technology that allows bidirectional functioning, thereby increasing compatibility across multiple environments.

Overall, VRP is a modern voltage stabilizer for modern day problems, and adapting to this technology is necessary to save you time and money down the line.